Home » Machines EN » inline dispersers

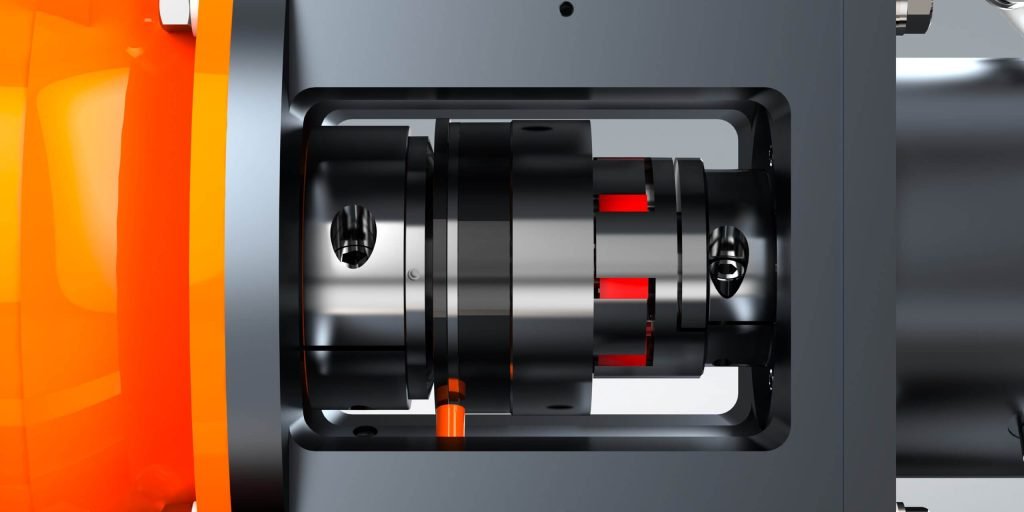

At RS Contracting, we take pride in our expertise in process technology, with over 25 years of experience in delivering customized solutions. Our Rmixx inline dispersing machines are the result of this experience, designed to meet the specific needs of our customers. Whether it’s dispersing powders in liquids or creating homogeneous mixtures, our advanced inline dispersing machines guarantee quality and efficiency. These machines are a perfect choice for dust-free powder induction and other complex mixing processes. Discover the possibilities of our RMZ Inline dispersers and RMC Inline powder dissolving machines, and experience how our state-of-the-art technology can optimize your production process.

Get in contact with us today for a solution that meets your specific requirements.

Rmixx RMZ Inline dispersers are ideal for the quick and efficient production of suspensions and emulsions in various sectors.

Rmixx RMC inline powder dissolvers are extremely suitable for the dust-free and efficient induction, dissolving, and dispersing of powders into liquids.

At RS Contracting, we have built a reputation as a reliable partner for customized process solutions. Our inline dispersers are designed to meet the highest standards of quality and efficiency.

Our inline dispersers are suitable for a wide range of applications, from mixing powders to producing emulsions and suspensions. With various configuration options, you can tailor our machines to your specific needs.

At RS Contracting, we stand for quality and reliability. Our inline dispersing machines are manufactured from high-quality materials and components, ensuring a long lifespan and minimal downtime.

Copyright © 2024 RS Contracting | All rights reserved | Web design/Implementation by SharpClicks