Gums and starch define texture and stability. They often take a lot of time to process. With the right inline dispersers you accelerate hydration dramatically. In many processes we see total process time cut in half with higher end quality. No extra additives. No extra handling. This keeps the line moving and yields more batches per day.

The challenge: powders that dust and form lumps

Hydrocolloids such as xanthan gum, guar, CMC, pectin, alginate and various starches are tricky. They dust easily. They float on the surface. They form lumps that stick to vessel wall and agitator. Once trapped, particles dissolve slowly. Mixing time increases, energy use rises and sieving steps may be needed. The time loss is caused mainly by poor wetting. Particles agglomerate as soon as they encounter moisture.

The solution: induct and disperse powder directly inline

With the right inline setup, the unit recirculates liquid and simultaneously inducts powders under high vacuum. Powder and liquid meet in an intense shear zone. There, particles are fully wetted instantly.

The result is wetting at particle level. Lumps do not get a chance. Viscosity builds as intended. The system runs in a closed loop with recirculation. A stable, high-quality dispersion is achieved in very short time.

What this delivers

- Hydration time for gums, starches and more is halved in many recipes

- Lower dosage is possible thanks to better particle deagglomeration and full activation

- Less rework; clean processing without dust and without air entrainment

How the process works

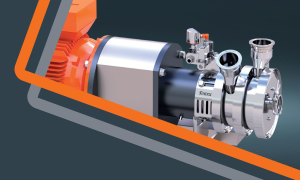

The inline powder induction machines from Rmixx induct powders from bag, hopper, big bag (FIBC) or silo. The induction rate is self-regulating; if powder feed slows due to friction or bridges in the powder, vacuum increases and the mass loosens again. No separate vacuum pump is required. The unit doses directly into the final batch; high‑strength premixes are often unnecessary.

After induction, the powder feed is closed and the system often recirculates briefly. Remaining micro‑agglomerates then disappear. The machine is CIP‑capable, built to EHEDG guidelines and can be cleaned without disassembly. It works regardless of the fill level in the tank. High viscosities are no problem.

Want to know what this approach can do for you? Explore our inline mixing and dispersing machines.

Use cases

- Yogurt or drinking dairy with modified starch: full wetting delivers a smooth mouthfeel and a stable final product. You can shorten recirculation time and avoid filtration.

- Sauces and dressings: xanthan gum, guar gum or CMC without lump formation. Plate heat exchangers remain free of fouling. Fewer cleaning stops are needed.

- Jam and gels with pectin: dosing stays tight and you reach target gel strength faster.

Quality and cost in balance

Inline powder induction shortens this critical process step. Hydration of gums and starches becomes faster and more complete. As a result, you can often use fewer auxiliaries while keeping texture and stability. Batch‑to‑batch variation drops. You also save energy because mixing and heating times are shorter. The line stays clean because there is less dust and no crusting on tank walls.

New to dispersing? Read our short explainer on what dispersing means and how it works. It shows when an inline setup delivers the most value.

What halving hydration time brings

The gains are in lead time and predictability. Less waiting makes planning tight. Customer orders ship sooner. Operators have less manual work and less cleaning. Equipment delivers more uptime. Quality becomes more consistent by avoiding air entrainment and lumps. Raw material savings are possible due to better activation. Costs drop without compromising texture or taste.

Implementation

We often start with a recipe and viscosity profile. Together we determine the right direction based on your requirements, consider layout options and ergonomics. Then we can develop a proposal or schedule a test straight away. This makes the impact on hydration time, dosage and taste immediately clear.

The machine can be integrated into existing setups. Control can be stand‑alone or via a plant control system. CIP and validation in food or pharma are familiar territory. RS Contracting delivers, installs and supports processes until the line runs as intended.

Ready for the next step

Do you want to halve hydration time for gums and starch and bring stability to your process? Contact RS Contracting on +31 524 522 722 or email [email protected]. Prefer a form? Go to our contact page. We are happy to think along and plan a first meeting or test quickly.