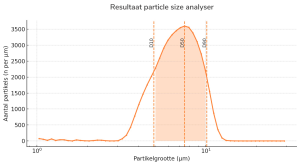

A uniform distribution of particles is often the difference between a smooth suspension and a lumpy final product. But how do you achieve an accurate particle size distribution (PSD) during fine dispersion work? The geometry of the rotor-stator, especially the slot width, plays a crucial role. This article explains how to make the right choices for your process.

What is Rotor-Stator Geometry?

A rotor-stator is a core component in mixing and dispersing equipment. The rotor spins at high speed, while the stator features precisely aligned slots. The liquid containing the particles is forced through these slots repeatedly. Their dimensions determine how many particles are reduced in size and to what extent. This technology is used across a wide range of industries, from food processing to chemicals and pharmaceuticals.

The Challenge: Unpredictable Particle Size

If you want a stable product with consistent properties, you need control over the particle size. When the slot width is not matched to the application, the distribution can become too broad or lumps may remain. This affects both quality and stability. Even small changes in geometry often have a bigger impact than you might expect.

Benefits of the Correct Slot Width

- Better control over PSD: you achieve the target distribution every time.

- Faster processing: finer results in fewer cycles.

- Lower risk of equipment overload or product degradation.

Matching Slot Width to Your PSD Target

The slot width determines how fine the rotor-stator can reduce particle size. For instance, if most particles need to be under 10 microns, you require a narrower slot than for coarser applications. If the slot is too narrow, blockages may occur; too wide, and the PSD remains too broad.

At RS Contracting, we always recommend in-process testing. For more background, see our introduction to dispersing.

Practical Tips for Your Process

- Always select a rotor-stator combination based on your target particle size, not default settings.

- When working with sensitive products, use interchangeable stators for added flexibility.

- Consider inline testing to determine the optimal setup right away. See our inline disperser range for available options.

Further Information or Personal Advice?

Want to know which rotor-stator combination best suits your fine powders, pigments, or emulsions? We are happy to advise. Visit our machines overview for more insight or contact us directly at [email protected] or call +31 524 522 722. Our specialists are ready to assist you.