Inline Vacuum Mixing of Viscous Suspensions: Eliminate Air, Improve Outcomes—Without a Vacuum Tank

Anyone who has ever mixed a thick, viscous mass in the process industry knows the challenge: entrained air. Air in products causes foam, unnecessary volume, and problems during packaging and downstream processing. The usual solution is a vacuum tank, but this is expensive to purchase and operate (long batch times, costly equipment). Inline mixing and dissolving of powders under vacuum offers a solution. In this article, we explain the principle and how to achieve smooth, air-free suspensions more easily.

What Is Inline Vacuum Mixing?

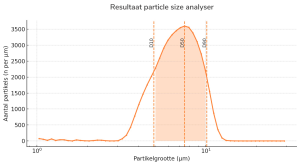

Inline vacuum mixing means removing air from the product during mixing—without the need for a costly vacuum tank. The necessary high vacuum is generated by the mixer itself. Viscosity and air bubbles are often linked; the higher the viscosity, the more air gets trapped. This is a common issue in adhesives and sealants, pastes, coatings, food bases, and cosmetics.

The Problem: Air Entrapment in Viscous Mixtures

Without vacuum, air gets trapped and cannot be removed, even with powerful mixers. The result: unwanted bubbles or voids in the final product, reduced shelf life, an unattractive appearance, and potentially lower batch volume. For manufacturers who demand top quality, this leads to extra work and wastage.

Advantages of Inline Vacuum Mixing

- Smoother, more homogeneously dispersed suspensions

- Minimal to zero air bubbles and foam formation

- Improved, predictable product properties

Additionally, you save time since downstream finishing and degassing are minimal. Processing is faster and packaging is easier, with less unwanted air in the product.

Practical Tips for Inline Vacuum Mixing of Viscous Suspensions

- Choose a mixer designed to handle solids under vacuum, such as inline powder dissolvers and dispersers from RS Contracting.

- Check all seals and connections for vacuum tightness to prevent air ingress.

- Allow room for expansion when filling; liquids and pastes may expand or contract under vacuum.

Examples: Applications of Inline Vacuum Mixing

- Paint and coating manufacturers who need streak-free pigment dispersion can maximize color strength and quality using inline vacuum technology. For more information, see our article on pigment dispersion.

- Producers of food-grade suspensions such as sauces or fillings obtain a smooth mixture without unwanted agglomerates or air bubbles.

- Cosmetics manufacturers achieve finer-textured creams with longer shelf life by avoiding entrapped air.

Find the Right Mixer for Your Vacuum Mixing Process

An effective vacuum mixing process requires the right equipment and expertise. Browse our range of inline dispersers or explore our full portfolio of mixing technologies to find what fits your application.

Need Expert Advice? Contact RS Contracting

Do you need advice on inline vacuum mixing of viscous suspensions? Call +31 524 522 722 or email [email protected]. Our specialists will provide tailored advice and the right technical solution for your process.